OPERATIONAL MODEL

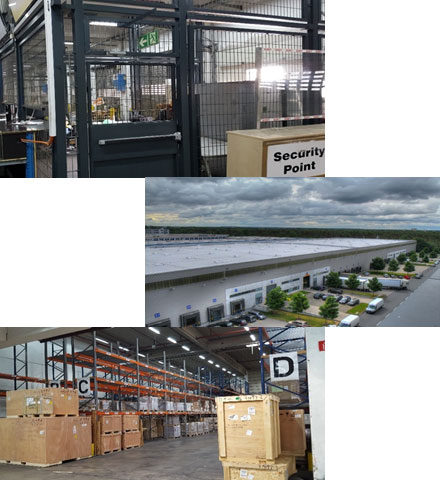

- Over 1.000.000 tons per year capacity

- 100.000 sqm warehousing area

- Highly secured facilities:

- CCTV

- Bio-metric card scanning doors

- Fences

- Security system

- 7 x-ray screening machines, 4 with dual view generators / 3D (1,80x1,80 metres)

- 2 Weight and Volumetric scanner

- 20 docks (with roller-beds)

- Cold rooms, VUN cage, DG storage

- Perfectly equipped

- Fully automated warehouse

- Paperless co-ordination and real-time information

- Speed / Efficiency / High quality

- Dedication and high-developed platform at optimized costing

- High investments in equipment, technology and IT segregation and non-congestion ramp transfers

CAPACITY PLANNING

- All operational components below are listed.

-

Actual time measurements are conducted for each operational process such as:

-

Truck loading/unloading time

-

Weight & Volume check time

-

Export palletizing time

-

X-Ray screening time

-

Transfer point operations time

-

Import breakdown time

-

Import delivery time

-

Import delivery preparation/loading/unloading time and operational timings are evaluated by the applied statistics techniques.

-

-

For each operational section; daily, monthly and annual calculations conducted with related parameters.

-

All capacity sections and constraints are benchmarked on a capacity overview page.